GL BARRIER is a comprehensive barrier product brand of barrier films with GL FILM at its core today maintains a leading share of the global market on account of world-class barrier performance and an extensive range of products for diverse purposes

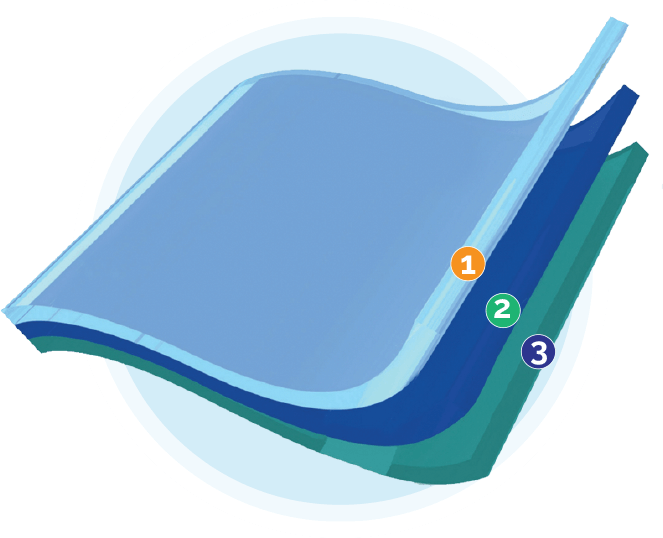

GL FILM consists of:

The film has many superlative properties and it is available in a variety of grades to best meet the intended application. GL BARRIER is known for its outstanding quality and has become the industry leader in transparent barrier films, and TOPPAN’s success can be seen as we maintain the largest market share throughout the world.

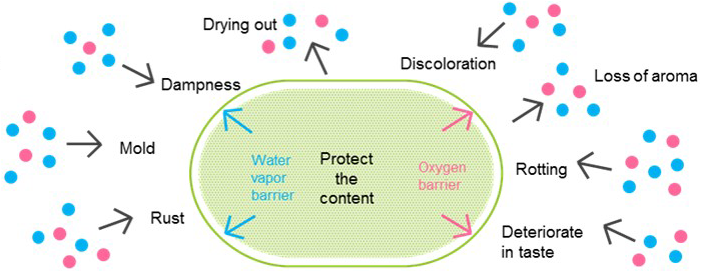

A barrier is a function of the film. It prevents oxygen, moisture and other substances from penetrating the film that may alter or deteriorate the quality of its contents. It is one of the most important functions of packaging or protective materials, and often extends the shelf-life for products that incorporate it.

Vapor Oxygen

GL FILM's high barrier performance protects contents from moisture, oxygen, and drying. It also provides a range of added value. GL FILM can be used to replace aluminum foil, and its transparency enables contents to be visible, thus enhancing their appeal to customers. Packages using GL FILM can also be heated in microwave ovens and inspected using metal detectors.

| Grade | Base Film | OTR (Metric/Imperial) | WVTR (Metric/Imperial) | Usage |

|---|---|---|---|---|

| GL-AE | PET 48ga / 12micron | 0.5 / 0.032 | 1 / 0.065 | Dry Goods |

| GX-P-F | PET 48ga / 12micron | 0.1 / 0.006 | 0.05 / 0.003 | Medical & Electronics where High OTR Needed |

| GL-AEC-F | PET 48ga / 12micron | 0.3 / 0.019 | 0.7 / 0.045 | Dry and Liquid Content- Hot Fill |

| GL-ARH-F | PET 48ga / 12micron | 0.3 / 0.019 | 1 / 0.065 | Semi-Retort - Liquid Content |

| GL-ARH | PET 48ga / 12micron | 0.3 / 0.019 | 1.3 / 0.084 | High Retort - Liquid Content |

| GL-RD | PET 48ga / 12micron | 0.2 / 0.013 | 0.3 / 0.019 | Various Product for Enhanced Post-Retort |

| GL-BP-F | PP 72ga / 18micron | 0.2 / 0.013 | 0.2 / 0.013 | Liquid Content / Hot-Fill / Boiling Condition and Recyclable Stream |

| No products found. Clear all filters. | ||||

Your message has been sent!